T SERIES

THE EVOLUTION IN THE FIELD

OF LEAK TESTERS

The reference for

the leak test

and the flow test

ForTest's differential measurement is the only real innovation in the field of Leak Testing in the last 40 years.

Never so easy

Forget about expensive and long installations thanks to the ease of use and the remote support of the Expert App Leak

Infinite database of resolved

application

With more than 10,000 applications resolved in 30 years, we will certainly have the solution ready for you

Immediate

set up

The extreme ease of use will allow you to optimize the implementation by making save you precious time.

Remote

support app

We cancel the distances to provide you constantly support and technical assistance with the innovative App Leak Expert

- DIFFERENTIAL DECAY LEAK TESTING

ForTest's differential system enables a "three-dimensional" analysis of leakage, decoupling it from noise and both thermal and mechanical phenomena. In contrast to traditional capacitive transducers, Dual Absolute® technology enables unprecedented measurement by isolating spurious variances between part and reference at intervals, thus obtaining a leakage value of only the leakage to be detected. Dual Absolute® is a worldwide exclusive from ForTest.

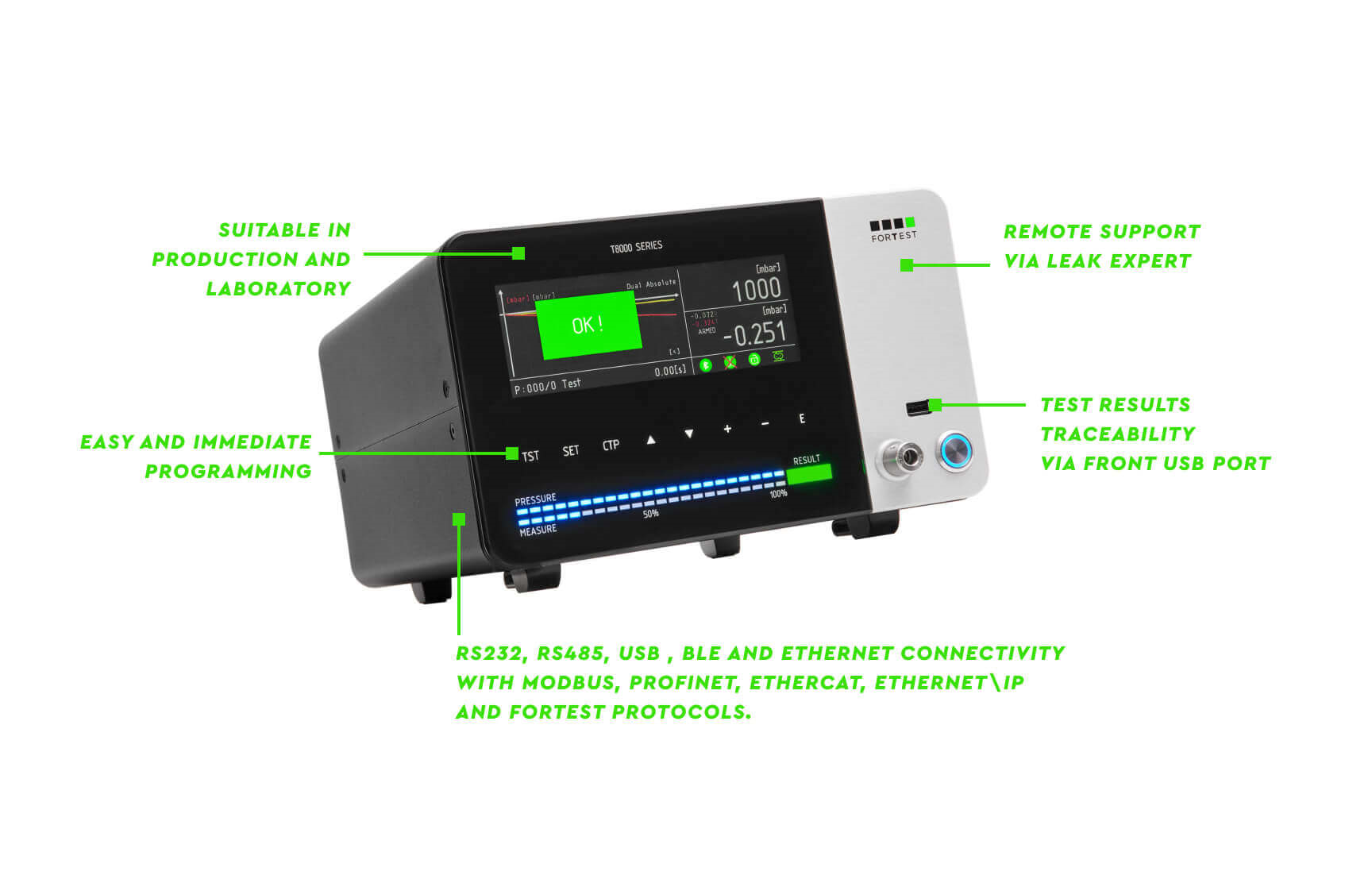

DIFFERENTIAL PRESSURE DECAY LEAK TESTER

- ABSOLUTE DECAY LEAK TEST

For years, absolute pressure decay measurement has been the miliarstone of ForTest. Originally developed for biomedical and nuclear applications, it is now the most widely used method for leak testing. Simple and reliable. 24 hours a day. Always.

ABSOLUTE PRESSURE DECAY LEAK TESTER

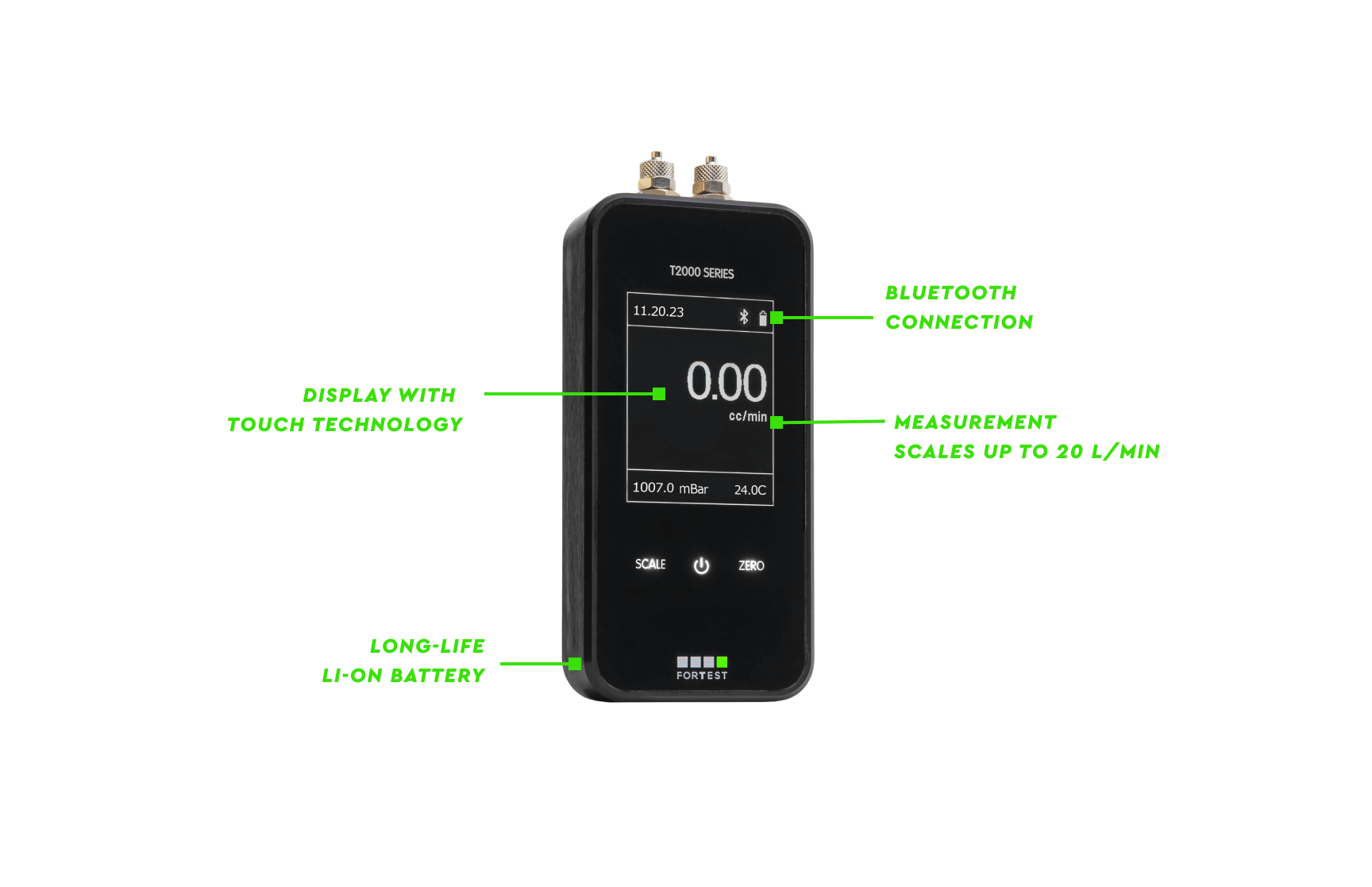

- FLOW TESTER

Massflow, massflow and more massflow! In over thirty years we have understood, selected, and solved every detail about the sensors and, more generally, of any physical principle.

Thus disposing both to the expertise in selecting suitable components according to the application and to all the software libraries that can optimize the quality of the measurement.

Without any doubt, and by way of example only, T8730 with electronic adjustment is definitely the best performing and most reliable product in the leak testing industry today.

MASS FLOW EQUIPMENT

- METROLOGY

Only through the verification of the testing process can you give your products a greater quality. The use of calibrated leaks or digital calibrators is now indispensable to certify its production, both from a qualitative and regulatory point of view.

METROLOGY EQUIPMENT

- SOFTWARE

The traceability of test results is the end point for end-of-line quality control. ForTest has developed software that integrates the operation of the control units with the information apparatus at the customer's disposal, from saving testing data through to the test graph. Technical support activities are also facilitated by the possibility of remote support directly on the test stations via the Leak Expert app.